CEREC Zahnersatz in München

Zahnersatz ganz ohne Abdruck planen und anfertigen? Das ist mit einer CEREC Zahnersatz Behandlung in München problemlos möglich, da hier die neueste Technologie für die digitale Behandlung verwendet wird. In einer Sitzung lassen sich professionell, schnell und exakt passende Modelle für den Zahnersatz oder für ein Inlay erstellen. Für strahlende Zähne und ein höheres Wohlbefinden – natürlich ohne dafür zu leiden oder lange zu warten.

Was ist CEREC Zahnersatz eigentlich?

Bei CEREC handelt es sich um eine Abkürzung für Ceramic Reconstruction. Die digitale Behandlungsform wird von einem Computer sowie von modernsten Programmen unterstützt und sorgt, passend zum Namen, für Zahnrestaurationen aus Keramik. Die genauen Details zu unserer verwendeten Technologie, finden Sie weiter unten auf der Seite. Damit sind ganze Zähne, Inlays, Kronen und Brücken innerhalb von kurzer Zeit erstellbar und lassen sich präzise einsetzen.

Der Unterschied bei dieser Behandlungsform ist die Tatsache, dass die gesamte Erfassung der Zähne und Erstellung der Versorgung digital funktioniert. Das geht für den Patienten mit deutlich weniger Zeit und Beschwerden einher als es sonst der Fall wäre. Eine CEREC Behandlung dauert in der Regel nur 90 bis 120 Minuten und Sie können unsere Praxis in München mit Ihrem neuen Zahnersatz verlassen.

Was sind die Vorteile einer CEREC Behandlung in München

Ein großer Vorteil von CEREC Zahnersatz in einer Sitzung ist ohne Frage die geringere Zeit, die erforderlich ist, um die Anfertigung von einem Zahnersatz geht. Vor allem die Verwendung von Abdrücken ist für viele Patienten weniger angenehm und führt teilweise zu einem Würgereiz oder zum Versuch, einen solchen zu vermeiden.

Ein Würgereiz ist daher bei der CEREC Zahnersatz Behandlung nicht zu befürchten, wodurch diese direkt deutlich angenehmer als die klassische Vorgehensweise wird. Weitere Vorteile von CEREC sind die Folgenden, die zu beachten sind:

- verhältnismäßig kostengünstig

- exakt angepasste Lösungen

- hochwertige und optimal verträgliche Option

- schnelle und einfache Lösung – auch für Patienten, die den Zahnarzt eher scheuen

- natürliche Optik durch farbliche Anpassung an die Nachbarzähne

- modernste und nahezu vollkommen schmerzfreie Lösung ohne weitere Umwege

- der Zahnersatz lässt sich innerhalb von einer Sitzung abschließend anfertigen

- die Ergebnisse lassen sich schon vorher am Bildschirm zeigen – für eine genaue Anpassung

Zahnersatz in einer Sitzung mit CEREC bei uns in München

Oftmals muss bei einem Zahnverlust sowie bei den meisten Restaurationen erst einmal mit einer provisorischen Lösung gelebt werden. Das ist für viele Patienten alles andere als angenehm, vor allem dann, wenn es sich um einen deutlich sichtbaren Schaden am Zahn oder um einen sichtbaren Zahnverlust handelt. Besonders hervorzuheben ist die Möglichkeit, mit CEREC Zahnersatz Behandlung in nur einer Sitzung direkt eine dauerhafte und eben nicht provisorische Lösung zu erhalten.

Die CEREC Zahnersatz Behandlung ist die Kombination von Schnelligkeit und Präzision. Während herkömmliche Verfahren oft mehrere Sitzungen und wochenlange Wartezeiten erfordern, kann der Patient in kurzer Zeit ein perfektes Ergebnis erzielen. Für alle, die Wert auf Zeitersparnis, Komfort und Qualität legen, bietet die CEREC Zahnersatz in einer Sitzung die ideale Lösung.

Natürliche und lange Haltbarkeit mit Keramik

Darüber hinaus zeichnet sich das verwendete Material aus Keramik dadurch aus, dass dieses fast nicht sichtbar ist und sich optisch sehr leicht an die übrigen Zähne anpassen lässt. Nicht zuletzt muss nicht befürchtet werden, dass eine kurze Haltbarkeit das Ergebnis dieser schnellen Lösung ist.

Den Erfahrungen zufolge hält der genannte Zahnersatz mehr als 30 Jahre und kann somit sogar länger als Gold verwendet werden. Es wundert daher weniger, dass Gold nicht mehr so sehr bei Zahnrestaurationen verwendet wird. Keramik zeichnet sich durch eine entsprechend große Härte auf, verfärbt nicht so leicht und sorgt auch nicht für dunkle Ränder am Zahnfleischrand.

Ablauf einer CEREC Zahnersatz Behandlung in München

Im ersten Schritt stellen wir gemeinsam in unserer Praxis fest, wie die aktuelle Situation Ihrer Zähne aussieht. Dafür wird unsere moderne, dreidimensionale Kamera verwendet, die genau erfasst, wie Ihre Zähne beschaffen sind, was zu beachten ist und welche Maße der Zahnersatz oder das Inlay aufweisen muss.

Dank modernster Technik werden alle wichtigen Daten in kürzester Zeit erfasst und bereitgestellt, was wesentlich schneller und exakter ist als es bei einem klassischen Zahnabdruck jemals der Fall sein könnte. Im nächsten Schritt erstellt unsere Software aufgrund der vorhandenen Daten ein exaktes Abbild des jeweiligen Zahnes.

Diese Daten nutzt dann unser spezielles Gerät, welches den Zahnersatz herstellt, der anschließend nur noch farblich an die Nachbarzähne angepasst und exakt zu fräsen ist. Ein so hergestelltes Inlay oder ein entsprechender Zahnersatz wird in die vorbereitete Lücke bzw. in den jeweiligen Zahn eingesetzt. Nach dem Polieren ist die CEREC Behandlung abgeschlossen, eine weitere Sitzung ist für die Versorgung nicht erforderlich.

Die neueste Technologie mit CEREC Zahnersatz

Für eine optimale Passgenauigkeit bei unseren Patienten ist es wichtig, die neueste Technologie zu verwenden, die exakte Ergebnisse mit sich bringt. Wir verwenden in unserer Praxis in München sowohl den Prime Scan Scanner als auch einen Primemill Fräser. Diese Technologien bringen den Vorteil mit, dass die Zähne exakt gescannt und der Zahnersatz ebenso exakt gefräst wird. Außerdem verwenden wir nur hochwertige Materialien, die sich durch ihre gute Verträglichkeit auszeichnen und die keine Beschwerden hervorrufen.

Schließlich ist bei einem Zahnersatz sowie bei jedem fremden Material im Mund wichtig, dass zum einen nur absolut verträgliches Material verwendet wird. Zum anderen spielt die exakte Passgenauigkeit eine sehr große Rolle und ist hier nicht zu unterschätzen. Ungenau angepasste Lösungen sorgen sonst nur für Beschwerden, die sich aber vermeiden lassen.

Abdruckfreie Scans mit CEREC Primescan

Vergessen Sie die alten lästigen Abdrucknahmen durchführen. Mit unseren CEREC Primescan können wir einen viel besseren & genaueren „digitalen Abdruck“ machen, ohne einen Abdruck machen zu müssen. Diese Technologie ist sehr präzise, erspart den Patientinnen und Patienten die Abdrücke und auch Zeit. Bei der digitalen Abformung scannt ein Laser die Oberflächen der Zähne und des Zahnfleisches. Die Software wandelt die gescannten Daten in 3D-Bilder um, welche direkt vom Zahnarzt geprüft werden können. Wenn Sie noch mehr Infos darüber erfahren wollen – sehen Sie sich gerne das kurze Video dazu an und überzeugen sich selbst.

3D-Planung – Digital Smile Design

Mit spezieller Software, Intraoralen 3D-Scans und Fotos der Patienten können Behandlungen digital geplant werden. Diese Planungen sind vor allem bei ästhetischen Arbeiten im sensiblen Frontzahnbereich wichtig. Zahnbewegungen mit Invisalign, Versorgung mit Veneers und andere Behandlungen können so gut visualisiert werden.

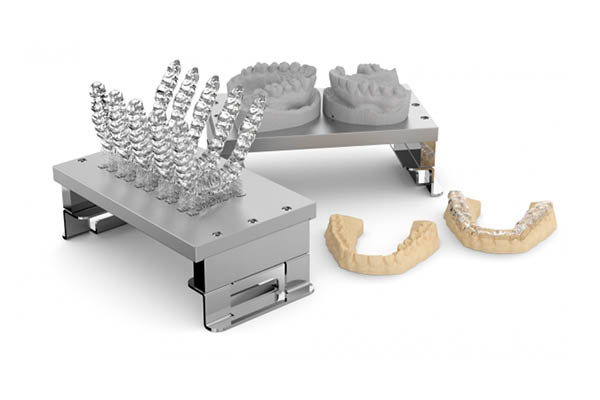

Cad/Cam – Fräsen

Zahnersatz (Kronen, Brücken, Implantatkronen etc.), Schienen und Provisorien können nach Digitalisierung von Modellen, oder direkt nach Intraoralscans am Computer designt und im Anschluss äußerst detailreich gefräst werden. Zum Einsatz kommen hier Kunststoffe, Metalle und auch Keramik.

3D-Druck

Mit 3D-Druckern ist es möglich nach Intraoralem Scan zum Beispiel Modelle. Aufbissschienen, Bohrschablonen und Provisorien zu drucken. Dabei kommt das DLP-Verfahren zum Einsatz, bei dem Die Werkstücke aus Flüssigen Kunststoffen durch UV-Lichthärtung hergestellt werden. Dabei kommen selbstverständlich nur Biokompatible Materialien zum Einsatz (Medizinprodukte der Klasse IIa)

FAQ rund um CEREC Zahnersatz in einer Sitzung bei uns in München

Wir nehmen im Folgenden nochmals einige häufige Fragen genauer unter die Lupe, die in Bezug auf CEREC Zahnersatz immer wieder aufkommen. Sollten Sie darüber hinaus noch Unklarheiten haben, sprechen Sie uns jederzeit gerne an

Die gesamte Behandlung findet in einer Sitzung statt. Pro Zahn gehen wir von einer gesamten Arbeitszeit zwischen 90 und 120 Minuten aus, sodass bei mehreren zu behandelnden Zähnen eventuell längere Zeiten anfallen. Die Zahnersatz Behandlung ist in einer Sitzung abschließend möglich, eine provisorische Versorgung ist hier nicht vorgesehen.

Wir verwenden bei der CEREC-Methode Keramik, da es sich hier um verträgliche und langlebige Optionen handelt, die optisch sehr nah an den echten Zahn herankommen.

Je nach Zahnhygiene und individuellen Möglichkeiten sowie der Ernährung ist von einer Haltbarkeit von rund 30 Jahren auszugehen. Eventuell ist der Zahnersatz auch länger einsetzbar. Teilweise übersteigt die Haltbarkeit die von Gold, sodass es sich um eine besonders langlebige Option handelt.

Nutzen kann so ziemlich jeder Patient die Zahnrestaurationen mit CEREC nach einer entsprechenden Beratung. Entscheidend ist das Ausmaß der vorhandenen Schäden, welches immer zu beachten ist. Ideal sind die Zahnrestaurationen in dieser Form, wenn eine schnelle, sofort einsetzbare und dabei metallfreie Lösung benötigt oder gesucht wird.

Ist der Zahn sehr stark beschädigt, kann es vorkommen, dass sich die Behandlung nicht mehr anbietet. Hierbei ist zu beachten, dass es bei starken Beschädigungen unter dem Zahnfleisch nicht mehr zu einer korrekten Erfassung durch den Prime Scan kommt.

Die Behandlung mit CEREC stellt daher nur eine Lösung dar, wenn die Beschädigung nicht zu stark ausfällt. Das können wir vor dem Beginn bereits durch ein Röntgenbild herausfinden und abklären, ob sich die Behandlung anbietet oder nicht.

Nein, der Prime Scan reicht für die Aufnahme der Zähne immer aus. Ein Abdruck, der manchen Patienten auch etwas unangenehm vorkommt, ist damit überflüssig.

Oft kann die Krone repariert werden, wenn nur ein kleines Stück des Zahnersatzes fehlt. Ist ein größeres Stück abgebrochen, muss die Krone eventuell ersetzt werden.

Nein, mit modernen Anästhesieverfahren ist es möglich, das Schmerzempfinden während der CEREC Behandlung vollständig auszuschalten.

Nach Abklingen der Betäubung können die Zähne sofort nach der CEREC Zahnersatz Behandlung belastet werden.

Ja, der Zahnarzt benötigt entsprechende Weiterbildungen, um die Anfertigung der Keramiken umsetzen zu können. Nur dann sind passgenaue Lösungen möglich, sodass wir stets auf dem aktuellen Stand bleiben, was die Technologien und mögliche Neuentwicklungen betrifft.

Sie sind an einer CEREC Zahnersatz Behandlung in München interessiert und wollen Ihre Zähne einfach, beschwerdefrei und vor allem schnell restaurieren lassen? Dann vereinbaren Sie jetzt Ihren Beratungstermin bei uns, um schon bald zu erfahren, welche Lösungen sich für Ihre Zähne anbieten!